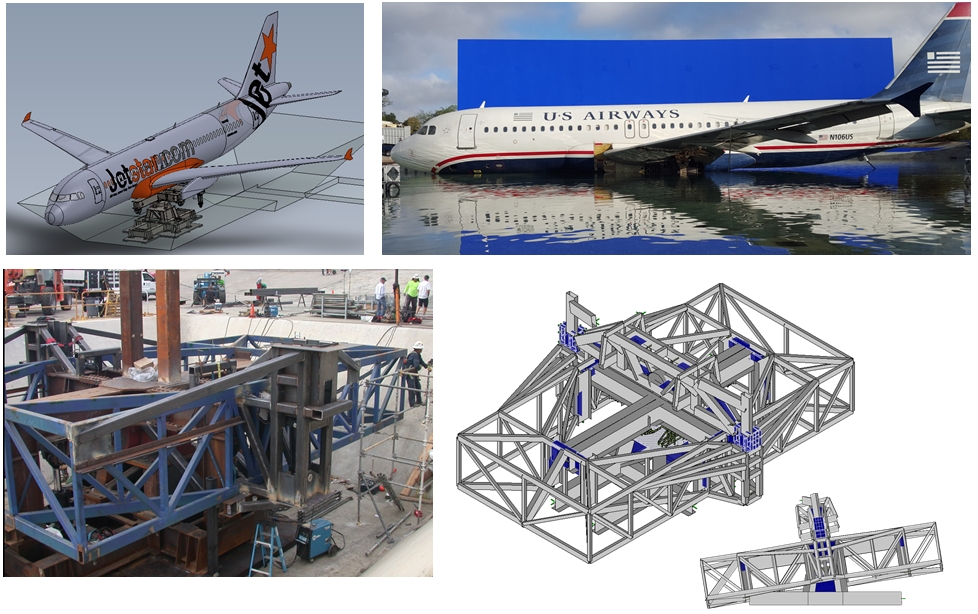

Challenge:

Our client requested that we analyze a mechanical gimbal to support an A320 Airbus for use in a production. The gimbal frame was 36′ long x 18′ wide x 6′ deep and supported a 200k plane. The gimbal was designed to pitch and roll up to 12 degrees about its two orthogonal axes and to vertically heave 4′-0″. The gimbal was primarily built out of W-beams, rectangular tube steel, and steel plate. Numerous structural observations were required to verify that the gimbal was built per the engineering specs.

Resolution:

To analyze the structural adequacy of the gimbal, the steel members, plates, and connections were modeled into RISA-3D, a commercially available structural modeling program. After the model was complete, appropriate dynamic forces were applied to simulate the forces on the gimbal while in motion. The saddles, connections, members, plates, and deflections were all verified against their code allowable limits. In addition to designing the gimbal, we engineered and designed a concrete foundation for the steel superstructure to sit on, including embedded anchors. Lastly, to meet our client’s expectations, numerous structural observations were performed during construction to ensure that the gimbal was built per our requirements.