Challenge:

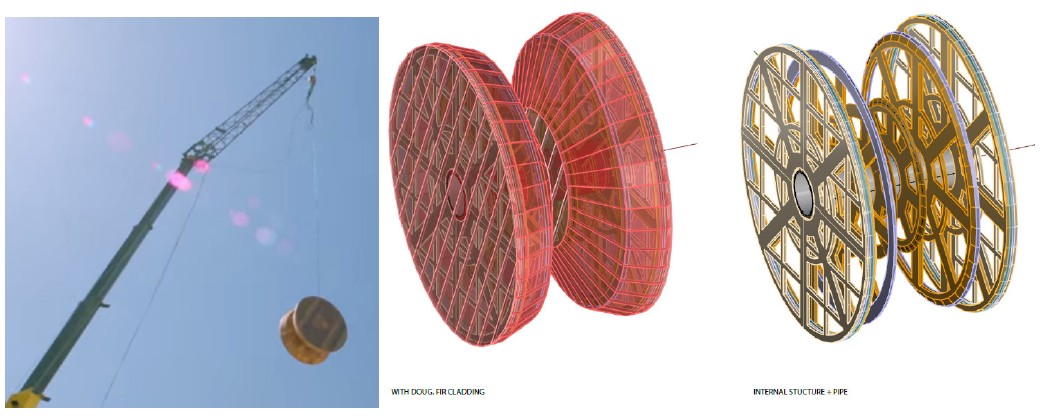

Our Client was hired by a major paint manufacturer to develop and construct one of the world’s largest functional wood yo-yo’s in order to promote their new line of products. The wood yo-yo was fabricated from an aluminum inner hub, with six CNC’d plywood inner spokes (as shown above). The spokes were then covered with Douglas-fir wood planks and painted with the manufacturer’s new product. The entire yo-yo was connected via standard wood glue and stapling and supported by an Amsteel fiber rope. The yo-yo was then dropped from a crane approximately 80 feet.

Resolution:

Hopper Engineering Associates was tasked with analyzing the yo-yo structure for translational and rotational dynamics and to determine if the yo-yo was in fact operational and structurally sound. The translational and centripetal forces were calculated and applied to the FE model (as shown below) to ensure the wood and connected elements were adequate and would not fly apart. Hopper Engineering made modifications to the hub connection and also was able to save weight, which was a secondary requirement. The result can be seen in the attached link and the performance of the yo-yo precisely matched the calculated results.