hallenge:

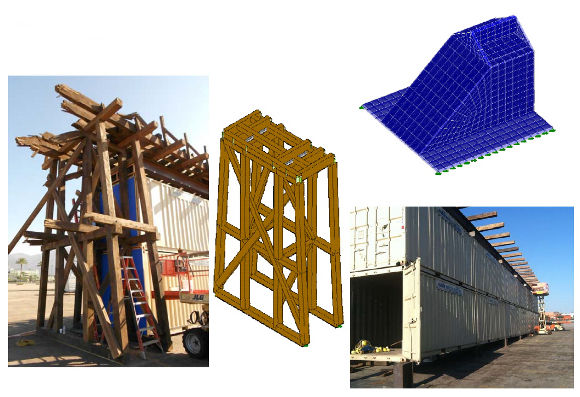

Our client requested we analyze and design an elevated platform capable of supporting a train engine weighing 75,000 lbs. The main structural system of the platform was made out of shipping containers, stacked two high, spanning 220 feet. Steel beams spanned between the shipping container end walls to provide support for a railroad track. On site conditions required the shipping containers to be shimmed 2-3 feet to level the track. The production also intended for the train to hit an emergency stop at the end of the line which would stop the train just as the lead wheels came off the rails.

Resolution:

In order to analyze the structural adequacy of the elevated platform: the supporting steel beams, shipping container end walls, transverse wooden supports, and emergency stop block were modeled into a commercially available structural modeling program. Then, using the calculated dynamic forces we ensured that the connections and lateral bracing could adequately support the lateral-forces caused by the train hitting the emergency stop block. In addition, a wooden extension was also designed to allow for part of the train to leave the shipping container trestle and be supported solely by the wooden substructure.