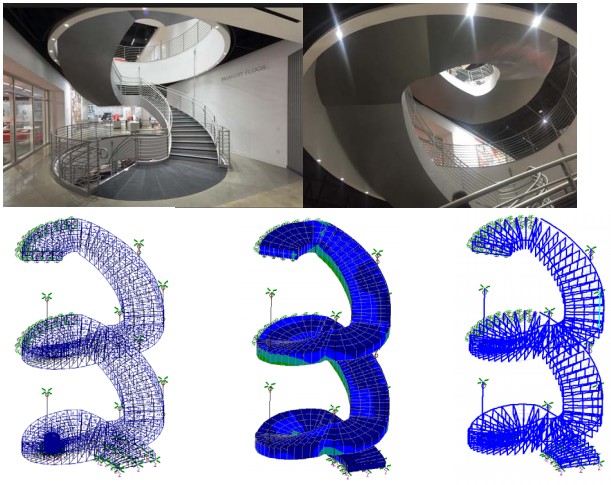

Challenge:

Hopper Engineering was requested to provide engineering support for a local car museums’ grand spiral staircase. The grand staircase was part of a larger multi-million dollar remodel of the museum. The staircase is constructed completely of steel. The staircase provides access and egress between the ground, second, and third floors. There is a single intermediate landing between each floor. Eachintermediate landing is attached to the floor above via 1″ diameter steel rods. Each of the main floor landings are anchored into the adjacent floor slab. The staircase is a permanent fixture and was permitted through the local building department.

Resolution:

In order to analyze the system, a finite element model was created of the entire staircase. All members and plates were modeled to provide the most accurate stress outputs. All code required dead, live and seismic loads wereapplied to the FE model. Stresses were then compared to the applicable codes for verification. Additional challenges for the loading and evaluation of the stairs included story shear displacements during a seismic event (which are required for egress staircases) and vertical load deflections of the adjacent floor slabs due to dead and live loads. These displacements and deflections were imposed on the staircase structure to ensure structural adequacy.