by GeorgeWebManHopperE | Mar 26, 2021 | Petrochemical Refining and Production

Multiple cracking and leak failures have occurred in tubing located within an oil refinery economizer. Metallurgical examination of the failed tubes indicates that corrosion fatigue is the most likely failure mechanism. HEA performed a finite element analysis and...

by GeorgeWebManHopperE | Mar 26, 2021 | Petrochemical Refining and Production

A J-tube previously used as a firewater source, located in a leg of an oil platform, was found to be plugged. A systems upgrade to the fire protection system requires a functional fire water pump at the leg. Flooding of the leg was under consideration as a solution....

by GeorgeWebManHopperE | Mar 26, 2021 | Petrochemical Refining and Production

New coke drums, which are larger than the existing ones, were to be installed. The table top support structure was also experiencing spalling of concrete on the underside as illustrated in the picture. HEA performed a dynamic analysis of the structure and drums and...

by GeorgeWebManHopperE | Mar 26, 2021 | Petrochemical Refining and Production

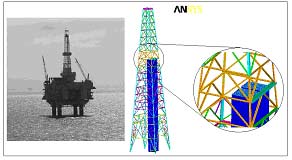

A rig in the Cook Inlet fleet was to be requalified for service by analysis for a 1000 year return period quake. HEA developed a finite element model to represent the platform, which accounted for the complex interaction between the drill pipe setback and the drilling...

by GeorgeWebManHopperE | Mar 26, 2021 | Petrochemical Refining and Production

A 70-ton valve used to automatically open the bottom head of a coke drum had to be supported from the existing concrete pedestal. HEA designed a support system capable of accommodating vessel thermal motions, seismic loads and maintenance activities, while remaining...