Challenge:

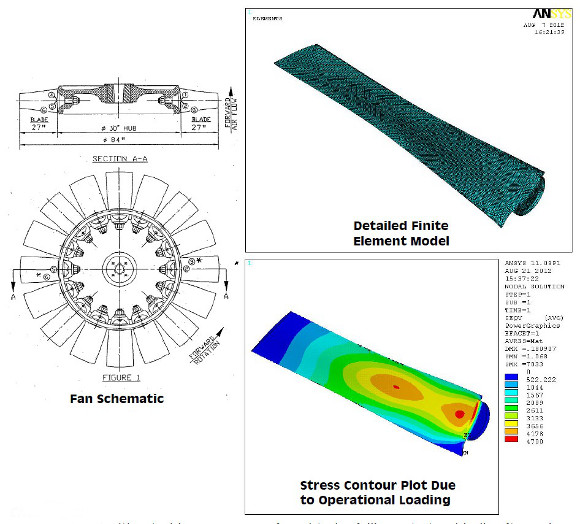

Fans associated with a turbine room were found to be failing catastrophically after only short periods of operation. Remediations were taken with regard to the intake airflow and the angle of attack of the blades. With these changes in mind, the facility operator wanted to ensure the steps taken would correct the problem by determining the new operational life expectancy of the blades.

Resolution:

Our engineering team created a detailed finite element model of the blade. Operational loads were applied and stress and strain results obtained. The as-tested strain data was compared to strain results from the analysis to ensure that the worst case dynamic strain values are considered in the life expectancy estimation. Finally a life expectancy was calculated based on a fatigue curve that was derived for the specific aluminum alloy of the blades. The modifications taken by the facility were shown to have extended the operational life expectancy considerably.