by GeorgeWebManHopperE | Mar 26, 2021 | Manufacturing

Post 9-11, many facilities require vehicle barriers for additional security. HEA modeled this vehicle and barrier using LS-DYNA. We performed a full dynamic impact analysis that accurately captured energy absorption and damage. The analysis showed that the barrier...

by GeorgeWebManHopperE | Mar 26, 2021 | Manufacturing

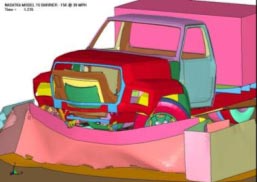

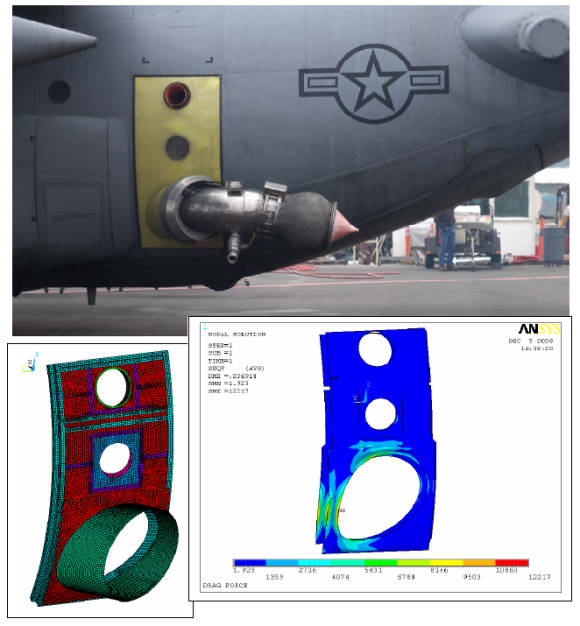

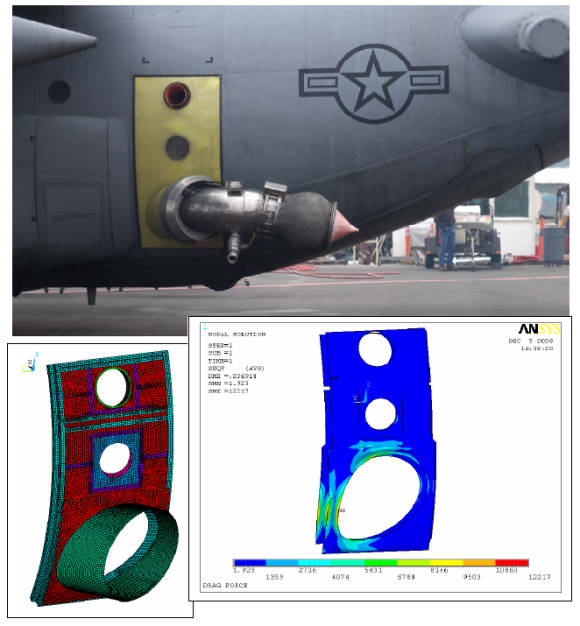

HEA was asked to redesign a support pallet for an airborne firefighting system. The system is mounted aboard a C-130 aircraft and sprays a fire-retardant foam mixture on forest fires. The original design had proved inadequate to handle the thrust caused by the...

by GeorgeWebManHopperE | Oct 23, 2020 | Manufacturing

Challenge: Demonstrate the structural adequacy of the C-130 aircraft paratroop door when used for firefighting missions. The outlet nozzle of the foam spray system passes through the door, causing drag force loading in combination with internal pressure and inertial...

by GeorgeWebManHopperE | Oct 23, 2020 | Manufacturing

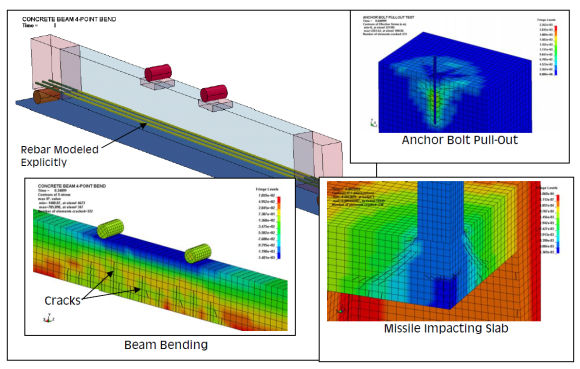

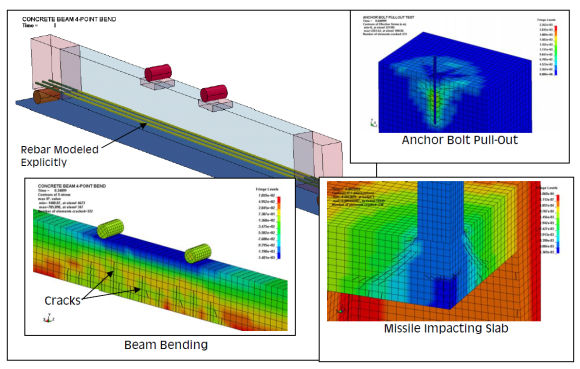

Challenge: A reinforced concrete structure required evaluation for the effects of an aircraft impact. The large expected deformations and highly non-linear behavior of concrete necessitated the development of a detailed finite element model of the structure in which...

by GeorgeWebManHopperE | Oct 23, 2020 | Manufacturing

Challenge: A BBRE booth which is 10′ x 12′ x 10′ tall is to be installed 12 feet above ground level for observation purposes. The structure will be subject to a high blast load of 25 psi incident pressure. Resolution: In order to reduce the load...

by GeorgeWebManHopperE | Oct 23, 2020 | Manufacturing

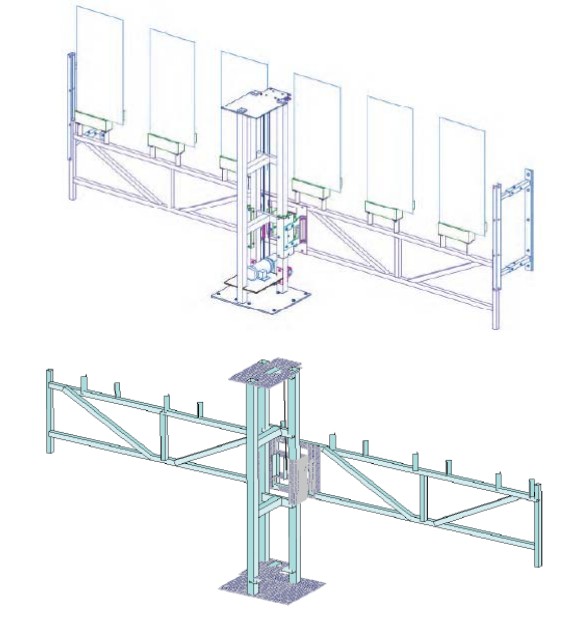

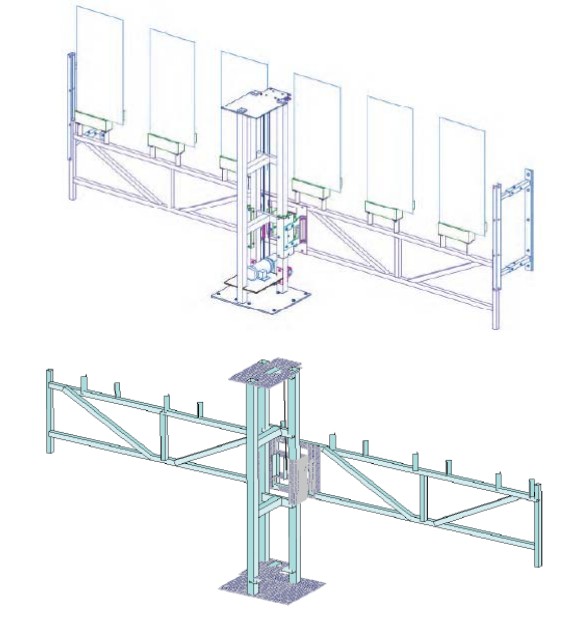

Challenge: To verify the structural adequacy of a motorized aluminum target lift system to support its self-weight, dynamic, and seismic loads. Special attention was required to account for the dynamic vertical movement of the motorized portion of the target lift...