T-AKE Vessel Bulwark Structural Evaluation

HEA performed a structural evaluation of the T-AKE vessel bulwark and its adjacent ship structure under the 26" lizard line cleat design load and sea state 5 loading conditions. A finite element model of the bulwark and adjacent ship structure was modified to reflect...

Foam Pump Flow Analysis

The flow from a fireboat foam pump system was not adequate. HEA evaluated the system and found the cause of the poor flow to be a pressure drop in the system. HEA recommended enlarging the foam feed piping from 1.5 inch diameter to 2 inch diameter and replacing the...

Self Contained Ratcheting Spreader Beam Design

HEA designed an adjustable spreader to be used with a shipyard's 300-ton cranes. The spreader employs a self-contained ratcheting system, which allows easy adjustments to accommodate different-sized loads. The spreaders are in service, where they have proven their...

Ship Spreader Beam Design

A large container ship was to be erected in a dock, which was designed for construction of a much lighter ship. HEA designed a spreader beam to distribute the ship's weight across sixty locations on the dock slab. The beams allowed for very large loads to be...

Monorail Rake

Challenge: The Traversing Bar Rake System (TBRS) is a trash rack raking system for the intake structure of a power plant. It consists of a monorail supported by several columns and a mechanized rake. The purpose of HEA's work was to establish the static seismic loads...

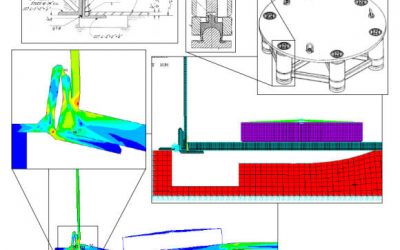

Transfer Cask Cup Design for the Spent Fuel Pool

Challenge: Design and analyze a Transfer Cask (TC) Restraint Cup for safe fuel transfer operations. The TC Restraint Cup will hold the TC in its desired position during fuel loading and prevent impact of the TC with any adjacent fuel racks during a seismic event....

Spent Fuel Handling Machine

Challenge: Modify an existing Spent Fuel Handling Machine (SFHM) by raising its hoists approximately four feet to provide the lift range necessary to load the Dry Storage Canister/Transfer Cask with spent fuel assemblies. The existing system was modified once before...

Fuel Storage Blast Analysis

Challenge: A nuclear power plant currently stores spent fuel in dry storage at an Independent Spent Fuel Storage Installation (ISFSI) at the site. The ISFSI consists of Dry Shielded Canisters (DSC) loaded with spent fuel which is housed in concrete Horizontal Storage...

Spent Fuel Pool Liner Degraded Concrete Evaluation

Challenge: Leakage of borated water from a Spent Fuel Pool (SFP) has lead to a hypothesized degradation of the slab and walls behind the liner up to a worst case calculated depth of 1.12 in. The purposes of our study were to evaluate the walls, slab, and stainless...

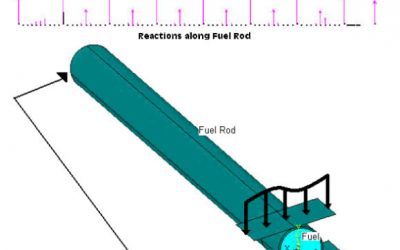

Fuel Rod Crush Stress

Challenge: Our firm was asked to calculate the stresses on two types of nuclear fuel rods due to a crushing load of an accidental side drop. The fuel rods are assembled in a basket containing several stacks of fuel rods. The fuel rods are separated by spacer grids,...