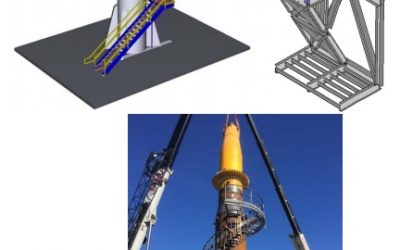

Offshore Platform Crane Pedestal Replacement

Challenge: The crane height on an offshore platform needed to be raised to avoid buildings on the platform from interfering with the crane boom's range of motion. The existing crane support structure must be verified and upgraded for increased loads from the new,...

Offshore Platform Inspection & Risk Reduction Program

HEA developed a process by which an offshore oil platform operator could minimize the risks to human safety and the environment from possible equipment or structural failure. HEA performed topside surveys and devised a program to screen and rank structural and...

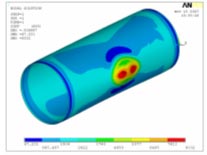

Finite Element Analysis to Determine Life Expectancy of a Pipe

A pipeline on the north slope was found to be dented during an inspection. HEA evaluated the pipe using finite element analysis. The results of our analysis were used to determine the additional risk resulting from the dent and the pipe's remaining service life.

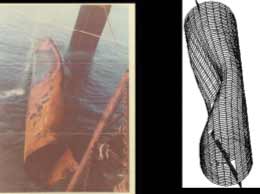

Structural Repairs to Increase Service Life

Ice severely damaged a horizontal brace of an oil platform jacket structure. HEA was tasked to determine the platform's fitness for service and remaining life. HEA analyzed the local and global stresses associated with the observed damage. Global elastic analysis of...

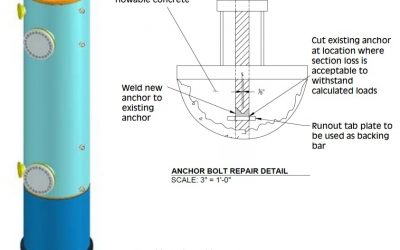

Anchorage Assessment and Repair

Challenge: The anchor bolts of twin 139 feet tall, 12 ftdiameter vertical vessels located inside a refinery are severely corroded. The clientasked us to evaluate the anchorage to determine which bolts are no longer adequate and to design the repair. Resolution: Field...

Cal Arp Seismic Analysis

This facility has a number of vessels, tanks, pipes and equipment containing Regulated Substances (RSes) as identified in the The California Accidental Release Program (Cal ARP). HEA helped to prepare and revalidate this facility's Risk Management Plan (RMP) with...

Vibration Analysis and Remediation

The cause of repeated cracking in the welded connection of a pipe stub from an 8" line to a bleeder valve was unknown. HEA attributed the failure to high fatigue stresses caused by resonant vibration of the valve. This vibration was traced to pressure pulsations in...

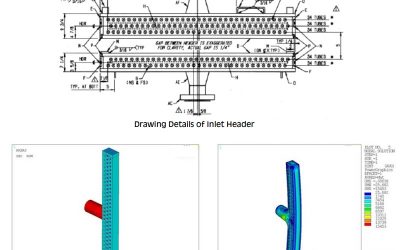

Air Cooler Rerate

Challenge: The air cooler for a refinery requires a rerate for a higher temperature and pressure. HEA was approached to evaluate the cooler's compliance with the requirements of the ASME code for structural adequacy. Resolution: Our engineering team used a combination...

Secondary Steel Inspection at a Refinery

A local refinery has requested an inspection of their secondary steel structures at their facility. The objective of this inspection program is to ensure that the safety of personnel who use these facilities is maintained. HEA developed inspection criteria and then...

Platform Analysis under Severe Seismic Load

The stability of a drilling platform, currently in the feasibility phase of development, is in question. The platform is supported by three composite legs embedded in the sea floor. The platform supports significant load from a drilling rig, drill pipe setback,...